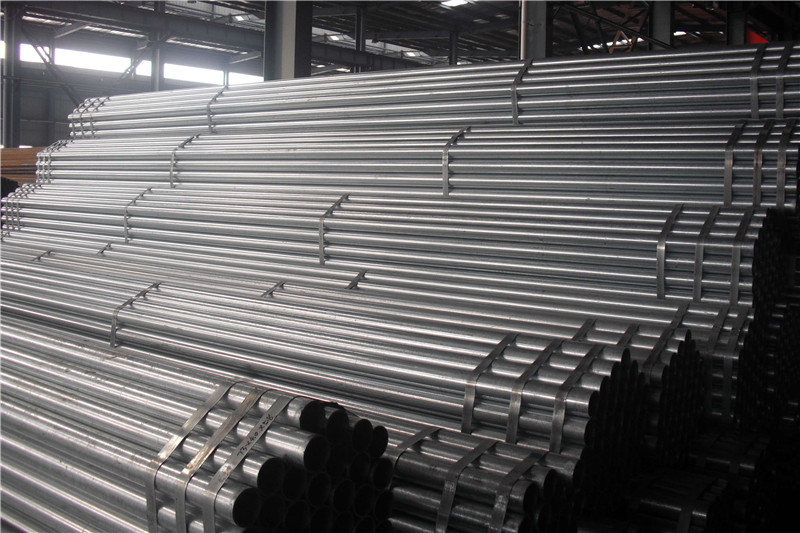

Igwe ọkụ eletrik / ọkụ na-etinye galvanized ígwè ọkpọkọ

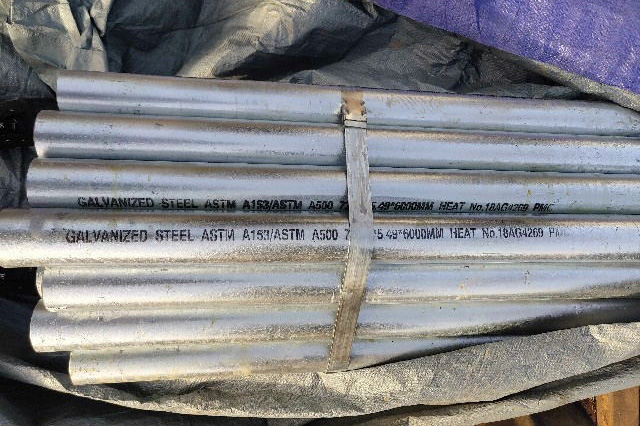

Galvanized ígwè ọkpọkọbụ ọkpọkọ nchara carbon nke ejiri akwa zinc kpuchie ya.Ihe oyi akwa zinc jere ozi dị ka ihe eji achụ àjà, ọ ga-enweta nchara n'ihu carbon ígwè n'okpuru ya.Galvanized ígwè ọkpọkọ na-agụnye abụọ ụdị: ọkụ-tinye galvanized ígwè ọkpọkọ na oyi galvanized ígwè ọkpọkọ.Igwe akwa galvanized ga-eme ka arụmọrụ mgbochi corrosion siri ike nke ọkpọkọ ígwè.

Hot itinye galvanizing bụ ime ka igwe a wụrụ awụ na ígwè matrix mmeghachi omume dị ka alloy oyi akwa, nke mere na mkpụrụ na mkpuchi abụọ jikọtara.Galvanizing na-ekpo ọkụ na-ekpo ọkụ bụ ibu ụzọ pịnye ọkpọkọ ígwè, iji wepụ ígwè oxide n'elu ọkpọ ígwè ahụ.Mgbe pickling, site ammonium chloride ma ọ bụ zinc chloride aqueous ngwọta ma ọ bụ ammonium chloride na zinc chloride agwakọta aqueous ngwọta tank maka ihicha, wee banye na-ekpo ọkụ itinye plating tank.Hot-mikpu galvanizing nwere uru nke edo plating, ike adhesion na ogologo ọrụ ndụ.Enwere ike ịnye ọgwụgwọ galvanized eletriki na ìhè & ọmarịcha elu.

Usoro galvanizing na-ekpo ọkụ:

Workpiece degreasing → ịsa → pickling → ịsa → ihicha ihe mgbaze itinye fluxing preheated ọkụ itinye galvanized → jụrụ oyi → emecha → itucha → ihicha → passivation ule

Usoro galvanized oyi:

Chemical degenreasing → ịsacha → mmiri ọkụ mmiri ọkụ electrolysis degreasing → ịsacha → siri ike corrosive galvanized iron alloy → ịsacha → ịsacha → ìhè → ịsa → ihicha passivation

Ihe owuwu na ihe owuwu

Mechanical na izugbe engineering ebumnuche

Imepụta ahụ ụgbọ ala