Mmanụ na-ebufe ọkụbụ ụdị mmanụ pụrụ iche nwere nkwụsi ike dị mma nke a na-eji maka nnyefe ọkụ na-apụtaghị ìhè.Okpomọkụ conduction mmanụ nwere ike ọ bụghị naanị izute kpo oku na jụrụ usoro chọrọ nke dị iche iche okpomọkụ na a wider nso nke okpomọkụ, ma na-aghọta usoro chọrọ nke elu okpomọkụ kpo oku na ala okpomọkụ jụrụ na otu okpomọkụ conduction mmanụ na otu usoro, nke nwere ike. belata mgbagwoju anya nke usoro na ọrụ.Ya mere, a na-eji usoro ikpo ọkụ ọkụ ọkụ na-eduzi mmanụ ọkụ na eriri kemịkal, ihe onwunwe na ụlọ ọrụ ndị ọzọ.

Njirimara nke sistemu mmanụ ọkụ conduction:

1.Under ọnọdụ nke fọrọ nke nta ka ikuku mgbali, nwere ike nweta nnọọ elu arụ ọrụ okpomọkụ - ya bụ, nwere ike dị ukwuu ibelata arụ ọrụ nrụgide na nchekwa chọrọ nke elu okpomọkụ kpo oku usoro, melite ntụkwasị obi nke usoro na akụrụngwa;

2.The okpomọkụ na-eduzi mmanụ ọkụ na-ahapụ usoro ọgwụgwọ mmiri na akụrụngwa, nke na-eme ka nrụpụta ọkụ nke usoro ahụ dịkwuo mma ma na-ebelata ọrụ nlekọta nke ngwá ọrụ na pipeline - ya bụ, ntinye ego mbụ na ụgwọ ọrụ nke usoro ikpo ọkụ nwere ike. ga-ebelata.

Ihe egwu nwere ike ime na arụ ọrụ sistemu mmanụ ọkụ:

1.Due na mpaghara ikpo ọkụ nke usoro kpo oku n'oge a na-eji mmanụ na-ekpo ọkụ na-ekpo ọkụ, mmeghachi omume na-ekpo ọkụ na-eme ka ọ dị mfe ime, na-eme ka oligomer na-egbuke egbuke na obere ọkụ.Polymerization n'etiti oligomers na-emepụta polymers na-adịghị ike na nke na-adịghị ike, nke ọ bụghị nanị na-egbochi ntinye nke ngwaahịa mmanụ ma na-ebelata otu arụmọrụ ọkụ ọkụ, ma na-ebutekwa ohere nke nrụrụ ọkụ na mpaghara na mgbawa nke pipeline.

2.Heat nnyefe mmanụ na etisasịwo ikuku na okpomọkụ na-ebu usoro ndochi bụ oxidation mmeghachi omume nke residual ikuku n'okpuru okpomọkụ ọnọdụ, na e guzobere organic acid na colloid na-agbasosi ike mmanụ pipeline, nke ọ bụghị nanị na-emetụta ọrụ ndụ nke okpomọkụ nyefe ọkara na na-egbochi pipeline, mana ọ na-ebutekwa corrosion acid nke pipeline n'ụzọ dị mfe ma na-abawanye ohere nke nkwụsị ọrụ sistemu.

Ihe mberede nke sistemu ikpo ọkụ na-ebufe mmanụ gụnyere:ọkụ nke okpomọkụ mkpuchi oyi akwa, ọkụ nke mgbasawanye tank iyuzucha na thermal mkpuchi oyi akwa, ọkụ nke okpomọkụ nnyefe mmanụ ọrụ ebe, ọkụ na mgbawa nke okpomọkụ nnyefe mmanụ nchekwa tank, ọkụ na mgbawa nke okpomọkụ nnyefe mmanụ okpomọkụ Exchanger ma ọ bụ reactor (kettle), Ọkụ gbawara, wdg. Ọ nwere ike hụrụ na ọtụtụ nkịtị thermal mmanụ kpo oku usoro ihe mberede bụ ihe ma ọ bụ obere metụtara ntapu.

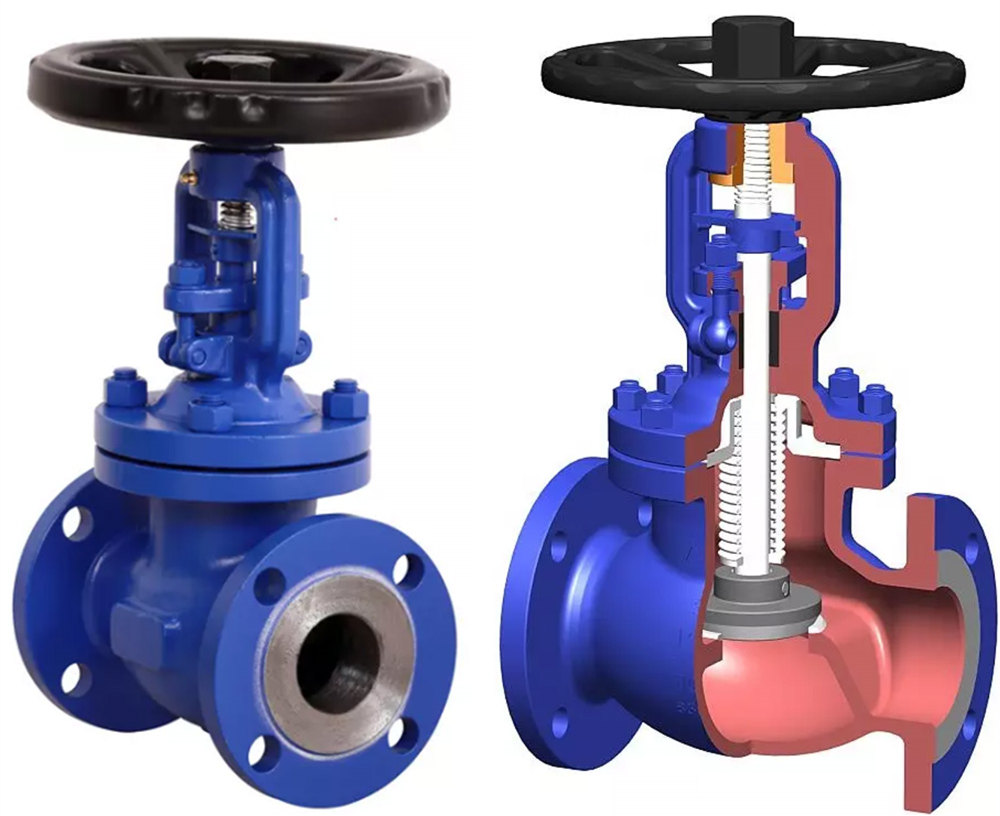

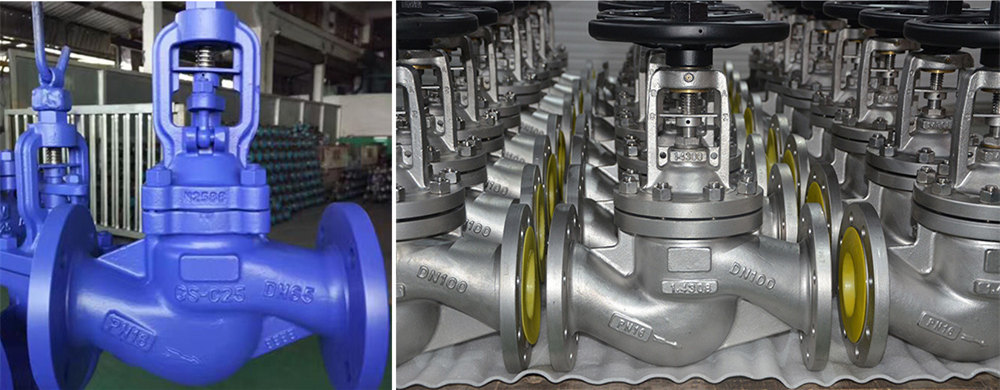

Ihe ndị chọrọ Valve maka ọkọlọtọ teknụzụ na nkọwapụta n'ụdị mmanụ ọkụ gụnyere: an iyuzucha valvụn'ebe kachasị elu na valvụ na-efe efe na ebe kachasị ala.A ghaghị ijikọ eriri ọkpọkọ nke usoro mmanụ ọkụ ọkụflangesewezuga oghere ngwaọrụ, ngwa ngwa ma ọ bụ valves.All ndị ọzọ interface na-welded.Nkeflangekwesịrị ịtọ uzo elu, na nominal mgbali ekwesịghị ịbụ ihe na-erughị 1.6MPa.N'ihi na okpomọkụ conduction mmanụ na okpomọkụ dị elu karịa 300 degrees, nominal mgbali nkeflangeekwesịghị ịbụ ihe na-erughị 2.5MPa.Flangesekwesịrị ịgbado n'úkwù kama ewepụghị flanges gbadoro anya.A naghị ekwe ka gasket flange nke sistem mmanụ ọkụ ka ọ jiri efere asbestos rọba, igwe ikuku igwe ma ọ bụ pad composite graphite gbasaa kwesịrị iji.Ekwesịrị ịnye usoro mmanụ ọkụ na-ekpo ọkụ na valvụ nchekwa, na valvụ nchekwa kwesịrị ịbụ valvụ mkpuchi mkpuchi nchekwa.

Ihe valvụ nke usoro mmanụ ọkụ agaghị atụba ígwè ma ọ bụ ígwè na-abụghị ígwè.N'ịtụle nrụgide dị ala ya, okpomọkụ dị elu na permeability siri ike karị, dị ka ọkọlọtọ teknụzụ nhazi nkọwa, pipeline mmanụ na-ekpo ọkụ na-ebipụ valvụ kwesịrị iji valvụ bellows akara valvụ, na-achịkwa valvụ kwesịrị iji bellows akara aka aka na-achịkwa valvụ, valvụ nchekwa na-eji. zuru oghe mgbịrịgba akara valvụ nchekwa.

N'ihi njirimara nke nkwụsi ike oxidation nke mmanụ na-eduzi okpomọkụ, nkwụsị nke valvụ mmanụ na-ekpo ọkụ ga-eme ka ọ bụghị nanị na-eme ka ọkụ nke mkpuchi mkpuchi ma ọ bụ ọkụ ọkụ na mgbawa nke ngwá ọrụ, ma na-eme ka mmeghachi omume oxidation nke mmanụ ọkụ na-agbaze na ikuku na-esi na ya. ikpe nke okpomọkụ, na-emepụta organic acid corrosion valve internals.Ya mere, valvụ mmanụ ọkụ na-ekpo ọkụ kwesịrị ọ bụghị nanị na ọ dịghị eme ihe ọ bụla n'ime ime, ma ọ dịghịkwa nkwụsị nke mpụga.

General mbukota globe valvụ mbukota site graphite nhazi ịkpụzi, ma ọ bụrụ na ịdị ọcha nke graphite ezughị, mmanụ ya na-eguzogide ga-adị nnọọ ogbenye, mgbe okpomọkụ conduction mmanụ n'ime graphite mbukota, ụfọdụ adịghị ọcha na graphite dị mfe agbaze site okpomọkụ conduction. mmanụ, na-akpata graphite ntụ ntụ, enweghị ike ime ka graphite mbukota iji nweta akara akara, nke a bụ isi ihe na-akpata mbukota valvụ mgbe leakage.Ihe mkpuchi bellow na-egbochi kọntaktị kpọmkwem n'etiti mmanụ ọkụ na graphite, nke na-edozi nsogbu nke mmanụ ọkụ na-esi na azuokokoosisi mgbe agbazere nkwakọ ngwaahịa graphite.

N'ihi na permeability nke okpomọkụ conduction mmanụ dị ike nke ukwuu (ihe dị ka ugboro 50 nke uzuoku), ọ bụrụ na ahọrọ filler akara, ọ dị nnọọ mfe ịgbapụta, na-eduga n'iyi nke mmanụ ọkụ, unyi akụrụngwa na ala, na bellows Ọdịdị. nwere ike kpamkpam ịghọta efu ntapu, na ọ dịghị eyi akụkụ.

N'ihi nwere ike ize ndụ nke ọxịdashọn kwụsie ike nke okpomọkụ conduction mmanụ, esịtidem akụkụ nke valvụ na-mere nke igwe anaghị agba nchara, nke nwere ike idi 425 ℃ elu okpomọkụ, corrosion iguzogide, na mgba ọkụ bụ karịsịa mfe.

Site na echiche ndụ n'ozuzu, ndụ ọrụ nke izugbevalvụ mkpuchi mkpuchidị mma karịa valvụ ndị ọzọ.Mmanụ na-enye ọkụ nwere nnukwu viscosity na nnukwu nguzogide na-asọ asọ na ọnọdụ oyi.Isi valvụ ahụ na-anabata ụdị mmeghe ngwa ngwa, nke nwere ike imeziwanye ọnụego na-agba ọsọ ma merie nkwụsị nke ọma mgbe ịmalite.Ya mere, iji hụ na nkwụsi ike nke mmepụta, kamakwa iji belata ụgwọ ọrụ na-arụ ọrụ n'ezie, usoro mmanụ ọkụ na-ebufe ọkụ kwesịrị ịhọrọ valvụ oghere ngwa ngwa nke isi.Bells akara nkwụsị valvụ, enweghị ike ịhọrọ valvụ nkwụsị nke nkwakọ ngwaahịa ma ọ bụ valvụ izugbe.

Bellows akara valvụ ụwanke BESTOP na-emepụta dị nnọọ mma maka igbupu ụgbọ njem pipeline nke usoro mmanụ ọkụ.

Oge nzipu: Jan-29-2023